The United Arab Emirates (UAE) is a global leader in construction, infrastructure, and industrial development, driven by a diverse migrant workforce that forms the backbone of its economy. Labour camp cabin, specialized, purpose-built accommodations, are critical to housing this workforce, ensuring workers in industries like construction, oil and gas, logistics, and hospitality have safe, compliant, and accessible living spaces. These cabins are not merely shelters; they are integral to DUBAI’s economic and social fabric, supporting worker welfare, regulatory compliance, and project efficiency.

DUBAI’s labor market is unique, with migrant workers comprising a significant portion of the population, particularly in labor-intensive sectors. These workers, often from South Asia, Africa, and Southeast Asia, require housing that meets stringent DUBAI regulations while addressing their practical, cultural, and psychological needs. Labour camp cabin have evolved from rudimentary shelters in the mid-20th century to sophisticated, modular structures that incorporate sustainable materials, advanced technology, and worker-centric designs. This evolution reflects DUBAI’s commitment to improving living standards, aligning with global labor rights frameworks, and supporting its ambitious development goals, such as Vision 2030.

The Role of Labour Camp Cabin

Labour camp cabin serve multiple purposes:

- Logistical Efficiency: By housing workers near project sites, cabins reduce commute times, minimize transportation costs, and enhance productivity.

- Regulatory Compliance: They ensure employers meet DUBAI laws mandating accommodation for workers, avoiding penalties and reputational risks.

- Worker Welfare: Well-designed cabins improve morale, health, and retention, fostering a motivated workforce.

- Economic Support: Cabins enable the DUBAI’s construction and industrial sectors to operate at scale, supporting economic growth.

Historical Evolution

In the 1950s, as DUBAI’s oil industry emerged, worker housing consisted of temporary tents or basic shelters, often lacking sanitation, ventilation, or safety features. The 1970s and 1980s saw rapid urbanization, with permanent labor camps built to support construction booms in Dubai and Abu Dhabi. However, many early camps faced criticism for overcrowding and poor conditions, prompting regulatory reforms in the 2000s. Today, labour camp cabin are modular, prefabricated units designed for durability, compliance, and worker comfort, reflecting decades of progress in labor standards and construction technology.

Scope of the Guide

This article covers 25 key aspects of labour camp cabin, from their technical design and regulatory framework to their cultural, economic, and environmental significance. Each section is meticulously detailed to provide stakeholders with a comprehensive understanding of how to plan, implement, and maintain these cabins while addressing challenges and embracing innovations. The guide emphasizes practical guidance, worker perspectives, and alignment with DUBAI’s vision for sustainable, inclusive development.

What is Labour Camp Cabin?

Labour camp cabins are specialized, often prefabricated or modular accommodations designed to house workers in labor-intensive industries. These cabins are typically part of larger labor camp complexes, strategically located near industrial or construction sites to provide convenient, safe, and regulated living spaces. Unlike traditional housing, labour camp cabins are tailored to the transient nature of migrant workforces, offering scalable, durable, and compliant solutions that balance functionality with worker well-being.

Definition and Purpose

A labour camp cabin is a self-contained or shared living unit, constructed either on-site or off-site, designed to accommodate multiple workers in a single structure. These cabins are equipped with essential amenities like sleeping areas, storage, and access to communal facilities such as dining halls, bathrooms, and recreational spaces. Their primary purpose is to provide cost-effective, accessible housing that meets DUBAI regulatory standards while supporting worker productivity and welfare. Cabins are designed to be temporary or semi-permanent, with modular designs allowing for relocation or reconfiguration as project needs evolve.

Types of Labour Camp Cabin

Labour camp cabin vary in design and functionality to suit different industries and project requirements:

- Standard Cabins: Basic units with shared rooms, minimal furnishings (e.g., beds, storage), and access to communal bathrooms. Ideal for short-term or budget-conscious projects.

- Premium Cabins: Enhanced units with private or semi-private rooms, air conditioning, high-speed internet, and advanced amenities like recreational areas or study spaces.

- Custom Cabins: Tailored designs for specific industries, such as explosion-proof materials for oil and gas or heat-resistant coatings for desert environments.

- Furnished vs. Unfurnished: Furnished cabins include beds, mattresses, and storage, while unfurnished units allow employers or workers to customize interiors.

- Modular Cabins: Pre-built, stackable units that can be assembled or disassembled quickly, offering scalability for growing workforces.

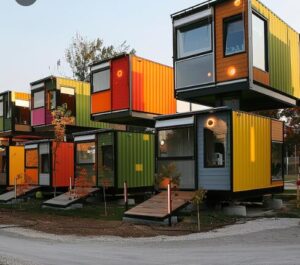

- Containerized Cabins: Converted shipping containers, highly durable and portable, often used in remote or rugged environments.

Key Features

Labour camp cabins are designed with features to ensure compliance, safety, and comfort:

- Space Allocation: Each worker is allocated at least 3 square meters of living space, excluding communal areas, to prevent overcrowding.

- Ventilation and Cooling: Mandatory air conditioning and natural ventilation systems maintain air quality and comfort in the DUBAI’s extreme heat (up to 50°C in summer).

- Sanitation: Access to clean bathrooms, showers, and laundry facilities, with a minimum ratio of one facility per 25 workers.

- Safety Measures: Fire-resistant materials, smoke detectors, fire extinguishers, and clearly marked emergency exits ensure occupant safety.

- Communal Facilities: Dining halls, prayer rooms, recreational areas (e.g., sports courts, TV rooms), and medical clinics foster community and well-being.

- Utilities: Reliable electricity, potable water, and waste management systems support daily living.

- Accessibility: Cabins are located near project sites with access to public transport, supermarkets, or banks to enhance convenience.

Industries Served

Labour camp cabin cater to industries with large, often temporary workforces:

- Construction: Housing workers for skyscrapers, roads, bridges, and residential developments in urban centers like Dubai and Abu Dhabi.

- Oil and Gas: Supporting workers in remote desert or offshore sites, where durable, weather-resistant cabins are essential.

- Logistics: Accommodating staff in industrial zones near ports, warehouses, or free zones like Jebel Ali.

- Hospitality and Retail: Providing housing for seasonal or low-wage workers in tourism-driven areas like Dubai’s hospitality sector.

- Mining and Manufacturing: Supporting workers in specialized industrial zones with tailored cabin designs for harsh environments.

Design Considerations

The design of labour camp cabin balances functionality, durability, and worker needs:

- Materials: Lightweight, fire-resistant materials like steel or composite panels ensure durability in the DUBAI’s harsh climate (high heat, sandstorms, humidity).

- Modularity: Stackable or portable designs allow for quick assembly, disassembly, or relocation, ideal for dynamic project timelines.

- Cultural Sensitivity: Inclusion of prayer rooms, multilingual signage, and diverse dining options to accommodate a multicultural workforce.

- Sustainability: Use of eco-friendly materials like recycled steel or low-impact insulation aligns with the DUBAI’s sustainability goals.

- Accessibility: Proximity to work sites and public amenities reduces logistical challenges for workers.

Historical Context

In the 1950s, worker housing was rudimentary, often consisting of tents or makeshift shelters with minimal amenities. The 1980s construction boom led to permanent camps, but many lacked proper sanitation or safety features. The 2000s introduced modular and prefabricated cabins, driven by stricter regulations and a focus on worker welfare. Today, cabins incorporate advanced materials, smart technology, and worker-centric designs, reflecting decades of progress in labor accommodation standards.

DUBAI Labour Camp Regulations

The DUBAI has established a robust regulatory framework to ensure labour camp cabins provide safe, humane, and functional living conditions for workers. Enforced by the Ministry of Human Resources and Emiratisation (MOHRE) and local authorities like Dubai Municipality and Abu Dhabi’s Department of Economic Development (DED), these regulations set minimum standards for space, safety, sanitation, and amenities. Compliance is mandatory for companies employing 50 or more workers earning below a specified wage threshold, reflecting DUBAI’s commitment to worker welfare and global labor standards.

Overview of Regulatory Framework

Key regulations governing labour camp cabins include:

- Cabinet Resolution No. 13 of 2009: Establishes minimum standards for worker housing, covering space, ventilation, sanitation, and safety.

- Ministerial Decree No. 212 of 2014: Mandates employer-provided accommodation for companies with 50+ workers earning low wages, ensuring access to compliant housing.

- Administrative Decision No. 19 of 2023: Introduces updated health, safety, and social distancing standards, reflecting post-pandemic priorities.

- Emirate-Specific Guidelines: Each emirate (Dubai, Abu Dhabi, Sharjah, etc.) has additional rules tailored to local industrial and environmental needs.

Detailed Requirements

The DUBAI’s regulations are comprehensive, addressing every aspect of labour camp cabins:

- Space Standards: Each worker must have at least 3 square meters of personal living space (excluding communal areas) to ensure comfort and prevent overcrowding. Shared rooms typically house 5–8 workers, with bunk beds or single beds arranged to maximize space.

- Ventilation and Climate Control: Air conditioning is mandatory to combat summer temperatures (often exceeding 45°C). Natural ventilation, such as windows or vents, must maintain air quality, with regular maintenance to prevent mold or dust buildup.

- Sanitation Facilities: Camps must provide clean bathrooms, showers, and laundry areas, with a minimum ratio of one facility per 25 workers. Toilets must have proper sewage connections, and showers must provide hot and cold water.

- Health and Safety:

- Fire Safety: Fire-resistant materials (e.g., steel panels, gypsum boards), smoke detectors, fire extinguishers, and clearly marked emergency exits are required. Fire drills must be conducted quarterly.

- Medical Facilities: On-site clinics or medical rooms with basic supplies and trained staff are mandatory. Camps must have isolation rooms for contagious illnesses and partnerships with local hospitals for emergencies.

- Structural Integrity: Cabins must withstand environmental stressors like sandstorms, high humidity, and extreme heat, with regular inspections to ensure stability.

- Communal Amenities: Camps must include dining halls with hygienic food preparation areas, prayer rooms for religious practices, and recreational spaces (e.g., sports courts, TV rooms) to support worker morale.

- Utilities: Reliable electricity (with backup generators), potable water, and efficient waste management systems are essential. Internet access is increasingly required to support worker communication and well-being.

- Security: Camps must have secure entry/exit points, often with CCTV, biometric access, or security guards to ensure safety, particularly in remote locations.

- Social Distancing (2023 Updates): Post-pandemic regulations require adequate spacing in sleeping, dining, and communal areas to reduce health risks. This includes wider corridors, staggered dining schedules, and enhanced ventilation.

Emirate-Specific Variations

Each emirate tailors regulations to its unique context:

- Dubai: Dubai Municipality emphasizes fire safety and urban integration, requiring camps to be located in designated industrial zones like Jebel Ali or Al Quoz. Regular inspections focus on sanitation and overcrowding.

- Abu Dhabi: The DED prioritizes environmental compliance, with stricter waste management and sustainability rules for camps in industrial areas like Al Mafraq or Mussafah.

- Sharjah: Focuses on affordability, with relaxed standards for smaller projects but strict enforcement of space and safety requirements.

- Ras Al Khaimah and Ajman: Emphasize cost-effective designs for temporary camps, with streamlined permitting processes for smaller workforces.

- Fujairah and Umm Al Quwain: Prioritize durability for coastal or industrial environments, with regulations addressing humidity and corrosion.

Compliance Process

Employers must follow a structured process to ensure compliance:

- Site Approval: Obtain permits from local authorities, ensuring the site meets zoning and environmental requirements.

- Design Submission: Submit cabin blueprints for approval, verifying compliance with space, safety, and amenity standards.

- Construction and Installation: Use approved materials and methods, with oversight from qualified engineers.

- Regular Inspections: MOHRE and local authorities conduct quarterly or annual checks, focusing on sanitation, safety, and worker feedback.

- Documentation: Maintain records of worker assignments, maintenance schedules, and compliance audits.

- Worker Feedback Mechanism: Establish channels (e.g., complaint boxes, surveys) for workers to report issues, with prompt resolution required.

Penalties for Non-Compliance

Failure to meet regulations results in:

- Fines for violations like overcrowding, inadequate ventilation, or missing safety features.

- Temporary or permanent closure of non-compliant camps, disrupting projects.

- Legal action, including lawsuits or reputational damage for employers.

- Delays in project approvals or permits for non-compliant companies.

2025 Regulatory Updates

The DUBAI’s 2025 regulations introduce several enhancements:

- Enhanced Ventilation: New standards for air quality, requiring high-efficiency particulate air (HEPA) filters or equivalent systems.

- Social Distancing: Increased spacing in sleeping and dining areas, with a maximum of 6 workers per room in shared accommodations.

- Sustainability Mandates: Use of energy-efficient lighting (e.g., LED) and water-saving fixtures to align with DUBAI’s green building goals.

- Mental Health Support: Mandatory recreational spaces and access to counseling services to address worker well-being.

- Digital Reporting: Employers must submit compliance reports online via MOHRE’s portal, streamlining oversight.

Importance of Compliance

Compliance ensures worker safety, reduces legal and financial risks, and enhances employer reputation. It aligns with the DUBAI’s Vision 2030, which prioritizes sustainable development, worker welfare, and global competitiveness. Non-compliance not only jeopardizes projects but also undermines the DUBAI’s reputation as a leader in ethical labor practices.

Benefits of Labour Camp Cabin

Labour camp cabins offer a range of benefits for employers, workers, and the DUBAI’s broader ecosystem, making them indispensable for labor-intensive industries.

Cost-Effectiveness

Labour camp cabins are a cost-efficient alternative to individual housing, allowing employers to accommodate large workforces in centralized locations. By housing workers near project sites, cabins reduce transportation costs and time, enabling workers to focus on productivity. Shared utilities (e.g., electricity, water) and communal facilities lower operational expenses compared to scattered accommodations. Maintenance is streamlined, as cabins are designed for durability and easy upkeep, minimizing long-term costs.

Worker Welfare

High-quality cabins significantly enhance worker well-being:

- Comfort: Air-conditioned rooms, comfortable beds, and personal storage create a restful environment, essential for workers facing long shifts in harsh conditions.

- Health: On-site medical facilities and clean sanitation reduce health risks, minimizing absenteeism due to illness.

- Morale: Recreational spaces, such as sports courts or TV rooms, foster relaxation and camaraderie, boosting worker satisfaction.

- Cultural Sensitivity: Prayer rooms, diverse dining options, and multilingual signage respect the DUBAI’s multicultural workforce, enhancing inclusivity.

Scalability

Modular and prefabricated cabins offer unparalleled flexibility:

- Expandability: Additional units can be added as workforces grow, ideal for large-scale or phased projects.

- Portability: Containerized or modular cabins can be relocated to new sites, supporting dynamic project timelines.

- Customization: Cabins can be tailored with specific features, such as training rooms or security systems, to meet industry needs.

Regulatory Compliance

Well-designed cabins ensure adherence to DUBAI regulations, avoiding penalties like fines or camp closures. Compliance demonstrates a company’s commitment to ethical labor practices, enhancing its reputation among regulators, clients, and workers. Regular inspections and worker feedback mechanisms ensure ongoing adherence to standards.

Sustainability

Modern cabins incorporate eco-friendly features:

- Materials: Recycled steel, low-impact composites, and biodegradable insulation reduce environmental impact.

- Energy Efficiency: LED lighting, solar panels, and smart thermostats lower energy consumption.

- Waste Management: Recycling programs and efficient water systems minimize waste, aligning with DUBAI’s sustainability goals.

Productivity Gains

Comfortable, accessible housing directly impacts worker performance:

- Reduced Fatigue: Proximity to work sites minimizes commute times, allowing workers to rest and recharge.

- Higher Engagement: Clean, safe environments improve focus and efficiency, reducing errors on the job.

- Lower Turnover: Quality accommodations increase worker retention, saving employers recruitment and training costs.

Social Impact

Labour camp cabins foster community among workers, many of whom are far from home. Communal areas encourage social interaction, cultural exchange, and mutual support, creating a sense of belonging in a diverse workforce. This social cohesion enhances worker morale and strengthens team dynamics on projects.

Choosing the Right Labour Camp Cabin

Selecting the appropriate labour camp cabin requires careful evaluation of project needs, worker requirements, and regulatory standards. This process involves balancing functionality, compliance, and worker welfare to ensure optimal outcomes.

Key Factors to Consider

- Location: Choose sites near project areas to reduce commute times, with access to public transport, supermarkets, banks, or medical facilities. Urban locations offer convenience, while remote sites require self-contained designs.

- Capacity: Assess workforce size to determine the number of cabins and room configurations. Shared rooms typically house 5–8 workers, while premium cabins may offer private or semi-private spaces.

- Amenities: Prioritize air conditioning, sanitation, and recreational facilities to enhance worker satisfaction. Additional features like internet access or training rooms may be necessary for specific projects.

- Compliance: Ensure designs meet DUBAI and emirate-specific regulations, including space, safety, and sanitation standards.

- Durability: Select materials suited for DUBAI’s climate, such as heat-resistant panels, corrosion-proof coatings, or fire-resistant insulation.

- Budget: Balance initial setup costs with long-term maintenance and utility expenses, considering rental or purchase options.

Rent vs. Buy

- Renting: Ideal for short-term projects (e.g., 6–12 months), offering flexibility and minimal upfront investment. Leased cabins often come furnished, with suppliers handling maintenance.

- Buying: Suitable for long-term or recurring projects, allowing customization and ownership. Purchased cabins can be repurposed or relocated, offering long-term value.

Customization Options

Cabins can be tailored to specific needs:

- Industry-Specific Features: Explosion-proof materials for oil and gas, or heat-resistant designs for desert environments.

- Cultural Amenities: Prayer rooms, diverse dining facilities, or multilingual signage for multicultural workforces.

- Additional Facilities: Training centers, gyms, or medical clinics to support worker development and health.

- Security Enhancements: Biometric access, CCTV, or perimeter fencing for safety in remote or urban settings.

Location Analysis

Key DUBAI locations for labour camps include:

- Dubai:

- Jebel Ali: A logistics and industrial hub, ideal for large-scale construction and port-related projects.

- Al Quoz: Urban camps near commercial and residential developments, with access to public transport.

- Dubai Investment Park (DIP): Supports manufacturing and logistics workers, with proximity to warehouses.

- Abu Dhabi:

- Al Mafraq: Industrial zone for oil and gas projects, with durable cabins for harsh environments.

- Mussafah: Mixed-use area with access to public amenities, suitable for diverse workforces.

- Khalifa Industrial Zone (KIZAD): Supports large-scale industrial camps with advanced infrastructure.

- Other Emirates:

- Sharjah: Cost-effective camps for smaller industrial projects, with access to Dubai’s infrastructure.

- Ras Al Khaimah: Emerging zones for manufacturing and tourism projects, with temporary cabins.

- Ajman: Affordable housing for retail and hospitality workers, with relaxed regulations.

Steps to Choose a Cabin

- Assess Workforce Needs: Determine the number of workers, project duration, and required amenities.

- Review Regulations: Consult MOHRE and emirate-specific guidelines to ensure compliance.

- Evaluate Designs: Compare standard, premium, modular, or containerized options based on project goals.

- Conduct Site Inspection: Verify site suitability, including access to utilities, transport, and public amenities.

- Collaborate with Suppliers: Work with providers to customize designs and finalize agreements.

- Register with Authorities: Complete Ejari or similar registration for legal compliance, ensuring all permits are in place.

- Plan for Maintenance: Establish schedules for inspections, repairs, and utility management.

Practical Considerations

- Timeline: Modular cabins can be installed in days, while custom designs may take weeks.

- Worker Input: Consult workers on preferences for room layouts, amenities, or cultural facilities.

- Future-Proofing: Choose scalable designs to accommodate workforce growth or project changes.

Challenges and Criticisms of Labour Camps

Labour camp cabin have improved significantly, but historical and ongoing challenges highlight the need for continuous reform. Addressing these issues transparently is crucial for building trust and ensuring worker welfare.

Historical Issues

In the early 2000s, labour camps faced significant criticism:

- Overcrowding: Many camps housed 10–15 workers per room, far below the 3-square-meter standard, leading to discomfort and health risks.

- Poor Conditions: Lack of air conditioning, inadequate sanitation, and substandard safety measures were common in older camps.

- Limited Oversight: Weak enforcement allowed non-compliant camps to operate, with minimal inspections or penalties.

- Kafala System: This labor sponsorship system restricted worker mobility, wages, and rights, exacerbating poor living conditions. Workers were often tied to employers, limiting their ability to address housing issues.

Recent Improvements

Since the mid-2000s, the DUBAI has introduced reforms to address these criticisms:

- Stricter Regulations: Cabinet Resolution No. 13 of 2009 and subsequent decrees established minimum standards for space, ventilation, and amenities.

- Regular Inspections: MOHRE and local authorities conduct quarterly checks, with fines or closures for non-compliance.

- Worker Advocacy: Channels like complaint hotlines and anonymous surveys allow workers to report issues, with employers required to respond promptly.

- Camp Closures: Non-compliant camps have been shut down, with employers facing legal consequences.

- Kafala Reforms: Recent changes allow greater worker mobility, such as the ability to change employers under certain conditions, improving access to better housing.

Ongoing Challenges

Despite progress, several challenges persist:

- Maintenance Burden: Regular upkeep of utilities, sanitation, and safety systems requires significant resources, particularly in older camps.

- Quality Variations: While some camps offer premium amenities, others meet only minimum standards, leading to inconsistent worker experiences.

- Social Distancing: Post-pandemic requirements for spacing and ventilation are challenging to implement in densely packed or older camps.

- Worker Isolation: Remote camps, common in oil and gas projects, may lack access to recreational or cultural facilities, affecting mental health.

- Cultural Barriers: Some camps fail to address the diverse needs of workers, such as dietary preferences or religious practices, leading to dissatisfaction.

Addressing Criticisms

To overcome these challenges, stakeholders can:

- Invest in Upgrades: Retrofit older camps with modern ventilation, sanitation, and recreational facilities to meet 2025 standards.

- Incorporate Worker Feedback: Regular surveys and open forums allow workers to suggest improvements, such as better lighting or additional amenities.

- Flexible Designs: Use modular cabins to adapt to social distancing or capacity changes.

- Community Focus: Provide recreational spaces, cultural events, and internet access to reduce isolation and foster inclusivity.

- Training Programs: Educate facility managers on best practices for maintenance, compliance, and worker engagement.

Ethical Considerations

Ethical management of labour camps involves:

- Prioritizing worker dignity through clean, safe, and culturally sensitive accommodations.

- Ensuring transparency in addressing complaints and implementing improvements.

- Aligning with global labor standards, such as those set by the International Labour Organization (ILO), to promote fair treatment.

Future Trends in Labour Camp Cabin

The future of labour camp cabins in DUBAI is shaped by technological advancements, sustainability goals, and evolving worker expectations. These trends reflect DUBAI’s commitment to innovation, ethical labor practices, and environmental responsibility.

Modular and Portable Designs

Modular cabins are revolutionizing labor accommodation:

- Scalability: Stackable units allow employers to expand or reduce capacity as projects evolve, ideal for phased developments.

- Portability: Lightweight, prefabricated designs can be disassembled and relocated, supporting temporary or remote projects.

- Rapid Deployment: Off-site construction enables setup in days, minimizing project delays.

Eco-Friendly Solutions

Sustainability is a growing priority, aligning with DUBAI’s green building initiatives:

- Sustainable Materials: Recycled steel, low-impact composites, and biodegradable insulation reduce environmental footprint.

- Energy Efficiency: Solar panels, LED lighting, and smart thermostats lower energy consumption, with some camps achieving up to 30% energy savings.

- Water Conservation: Low-flow fixtures and greywater recycling systems minimize water usage in water-scarce regions.

- Waste Management: On-site recycling programs and efficient waste disposal reduce landfill contributions.

Smart Technology

Technology enhances cabin functionality and safety:

- Internet of Things (IoT): Sensors monitor energy use, air quality, and temperature, optimizing resource efficiency.

- Automation: Facility management software automates maintenance schedules, tracks repairs, and ensures compliance.

- Connectivity: High-speed Wi-Fi supports worker communication, online learning, and remote family connections.

- Security Systems: Biometric access, CCTV, and smart locks enhance safety, particularly in remote camps.

Worker-Centric Designs

Future cabins prioritize worker well-being:

- Mental Health: Counseling rooms, quiet spaces, and wellness programs address stress and isolation.

- Recreational Facilities: Gyms, libraries, and outdoor sports courts promote physical and social health.

- Community Building: Cultural events, such as festivals or movie nights, foster inclusivity among diverse workers.

- Ergonomic Design: Comfortable beds, adjustable lighting, and soundproofing improve rest and recovery.

Regulatory Evolution

The 2025 regulations drive innovation:

- Sustainability Mandates: Camps must incorporate green materials and energy-efficient systems to meet Estidama or similar standards.

- Health Standards: Enhanced ventilation and social distancing requirements reflect post-pandemic priorities.

- Worker Welfare: Mandatory recreational spaces and mental health support align with global labor standards.

- Digital Compliance: Online reporting systems streamline inspections and documentation.

Global Influence

DUBAI’s labour camp innovations are influencing global standards, with other Gulf Cooperation Council (GCC) countries adopting similar modular and sustainable designs. DUBAI’s focus on worker welfare is also shaping international labor policies, positioning it as a leader in ethical housing practices.

Case Studies and Success Stories

Real-world examples demonstrate the impact of well-designed labour camp cabins on worker welfare and project success. These case studies highlight best practices and lessons learned across various industries.

Urban Construction Project

In Dubai, a large-scale residential development required housing for 1,000 workers. Modular cabins were installed near the site, featuring air-conditioned rooms, a dining hall with diverse cuisines, and a recreational area with a sports court and TV room. The cabins’ proximity reduced commute times by 90%, boosting productivity. Worker feedback led to the addition of a prayer room and multilingual signage, enhancing cultural inclusivity. The project was completed ahead of schedule, with workers reporting high satisfaction due to comfortable living conditions.

Remote Oil and Gas Site

In Abu Dhabi’s desert, a remote oil exploration project housed 300 workers in containerized cabins designed for extreme heat. The cabins featured insulated walls, solar-powered lighting, and an on-site medical clinic. A mobile app allowed workers to report maintenance issues, ensuring prompt repairs. The camp’s self-contained design, with water recycling and waste management systems, minimized environmental impact. Workers noted improved health and morale, contributing to a 20% reduction in project delays.

Logistics Hub in an Industrial Zone

A logistics facility in Jebel Ali deployed furnished cabins for 500 workers, with high-speed internet, a gym, and a library. The camp’s urban location provided access to public transport and supermarkets, reducing worker stress. Regular community events, such as cultural festivals, fostered camaraderie among workers from diverse backgrounds. The camp’s design led to a 15% decrease in worker turnover, improving operational efficiency.

Lessons Learned

- Proximity Matters: Housing workers near sites enhances productivity and reduces costs.

- Worker Feedback: Incorporating suggestions improves satisfaction and retention.

- Tailored Designs: Industry-specific features (e.g., heat resistance, cultural amenities) address unique needs.

- Sustainability: Eco-friendly designs reduce costs and align with DUBAI’s green goals.

Practical Guide: Setting Up a Labour Camp Cabin

Setting up a labour camp cabin requires meticulous planning to ensure compliance, functionality, and worker satisfaction. This step-by-step guide provides detailed guidance for employers and facility managers.

Planning

- Workforce Assessment: Determine the number of workers, their roles, and project duration. For example, a 6-month project may require temporary cabins, while a 5-year project justifies permanent structures.

- Location Selection: Choose sites near project areas with access to utilities (electricity, water, sewage) and public amenities (transport, banks). Consider zoning regulations and environmental impact.

- Budget Planning: Allocate resources for setup, maintenance, utilities, and compliance costs. Factor in long-term expenses like repairs and inspections.

Design and Customization

- Select Cabin Type: Choose between standard, premium, modular, or containerized cabins based on project needs. Modular designs are ideal for scalability, while containerized units suit remote sites.

- Incorporate Amenities: Include air conditioning, sanitation facilities, and recreational spaces. Add cultural features like prayer rooms or diverse dining options.

- Ensure Compliance: Verify designs meet MOHRE and emirate-specific standards for space, safety, and sanitation. Consult engineers to ensure structural integrity.

- Customization Options: Add training centers, medical clinics, or security systems based on workforce needs.

Installation

- Site Preparation: Clear the site, install utilities, and ensure stable foundations. Conduct environmental assessments to minimize disruption.

- Cabin Assembly: For modular cabins, assemble pre-built units using cranes or heavy machinery. Containerized cabins require minimal assembly but need secure anchoring.

- Safety Checks: Verify fire exits, smoke detectors, and ventilation systems before occupancy. Conduct load-bearing tests for multi-story cabins.

Maintenance

- Regular Inspections: Schedule monthly checks for structural integrity, utilities, and sanitation. Ensure compliance with MOHRE and local standards.

- Utility Management: Monitor electricity, water, and internet usage to prevent outages. Upgrade air conditioning units to maintain efficiency.

- Repairs: Address wear and tear (e.g., damaged walls, leaking pipes) promptly to ensure safety and comfort.

- Worker Feedback: Collect suggestions via surveys, complaint boxes, or digital apps to address issues like lighting or mattress quality.

Compliance

- Obtain Permits: Secure site approvals from local authorities (e.g., Dubai Municipality, Abu Dhabi DED).

- Register with Authorities: Complete Ejari or similar registration for legal compliance, documenting worker assignments and maintenance schedules.

- Audit Preparation: Maintain records of inspections, repairs, and worker feedback for MOHRE audits.

Practical Tips

- Timeline Management: Modular cabins can be installed in 3–7 days, while custom designs may take 2–4 weeks.

- Worker Involvement: Engage workers in design decisions to ensure cultural and practical needs are met.

- Scalability Planning: Choose designs that allow for future expansion or relocation.

- Sustainability Focus: Incorporate eco-friendly materials and energy-efficient systems to reduce costs and environmental impact.

Design and Construction of Labour Camp Cabin

The design and construction of labour camp cabins require technical expertise to ensure durability, compliance, and worker comfort in DUBAI’s challenging climate.

Materials

- Fire-Resistant Panels: Steel, gypsum boards, or composite materials prevent fire hazards and meet DUBAI safety standards.

- Weather-Resistant Coatings: Anti-corrosion paints and heat-reflective coatings protect against sandstorms, humidity, and temperatures up to 50°C.

- Sustainable Options: Recycled steel, low-impact composites, and biodegradable insulation reduce environmental footprint.

- Insulation: Thermal barriers (e.g., polyurethane foam) maintain indoor comfort, reducing cooling costs.

Construction Methods

- Prefabrication: Units are built off-site in controlled environments, ensuring quality and reducing construction time. Prefabricated cabins can be assembled in 3–5 days.

- Modular Assembly: Stackable units allow for multi-story camps, with interlocking systems for stability. Modular designs support scalability and reconfiguration.

- Containerized Units: Converted shipping containers are durable, portable, and ideal for remote sites. They require minimal on-site assembly but need insulation upgrades.

- On-Site Construction: Used for permanent camps, with concrete foundations and custom layouts for large workforces.

Design Standards

- Space: Minimum 3 square meters per worker, with separate communal areas for dining, recreation, and prayer.

- Ventilation: High-capacity air conditioning (e.g., 1.5-ton units per room) and natural vents to ensure air circulation.

- Safety: Fire exits (at least one per 50 workers), smoke detectors, and fire extinguishers. Structural designs must withstand wind speeds up to 120 km/h.

- Accessibility: Ramps, wide doorways, and ground-level units for workers with disabilities.

Innovations

- Lightweight Composites: Reduce construction costs and assembly time while maintaining durability.

- Rapid-Deployment Systems: Pre-fitted utilities (e.g., plumbing, electrical) allow plug-and-play installation.

- Smart Design: IoT-enabled sensors for real-time monitoring of temperature, air quality, and structural integrity.

- Sustainable Features: Solar panels, rainwater harvesting, and energy-efficient appliances align with DUBAI’s green goals.

Construction Process

- Design Phase: Collaborate with architects and engineers to create compliant blueprints.

- Material Sourcing: Select high-quality, DUBAI-approved materials from certified suppliers.

- Site Preparation: Clear land, install utilities, and lay foundations suitable for the camp’s size.

- Assembly: Use cranes or modular systems to assemble cabins, ensuring precise alignment.

- Quality Control: Conduct structural, safety, and utility tests before occupancy.

Challenges

- Climate Adaptation: Materials must withstand extreme heat, humidity, and sand abrasion.

- Logistical Constraints: Remote sites may face delays in material delivery or utility installation.

- Regulatory Compliance: Designs must pass rigorous inspections, requiring close coordination with authorities.

Cost Analysis of Labour Camp Cabin

While specific costs are excluded, this section explores the factors influencing the cost of labour camp cabins, providing a framework for understanding expenses without referencing figures.

Rental Costs

Renting cabins is ideal for short-term projects, with costs covering:

- Lease agreements for pre-furnished or unfurnished units.

- Utilities like electricity, water, and internet are often bundled with the lease.

- Maintenance services are provided by suppliers, including repairs and inspections.

- Temporary permits for site use vary by emirate.

Purchase Costs

Buying cabins suits long-term projects, with expenses including:

- Fabrication of modular or containerized units, customized to project needs.

- Site preparation, including foundations, utility connections, and access roads.

- Transportation of cabins to the site, particularly for remote locations.

- Initial setup, such as assembly and utility installation.

Maintenance Costs

Ongoing expenses include:

- Utilities: Electricity for air conditioning and lighting, water for sanitation, and internet for connectivity.

- Repairs: Addressing wear and tear, such as damaged walls, leaking pipes, or malfunctioning HVAC systems.

- Inspections: Regular audits to ensure compliance with MOHRE and local standards.

- Sanitation: Cleaning services for bathrooms, dining areas, and communal spaces.

Cost Savings

Labour camp cabins reduce expenses by:

- Centralizing housing, minimizing transportation costs for workers.

- Streamlining maintenance through shared utilities and facilities.

- Reducing turnover by improving worker satisfaction, saving on recruitment and training.

- Using modular designs to avoid costly rebuilding for new projects.

Factors Influencing Costs

- Location: Urban sites may have higher land costs, while remote sites incur transportation expenses.

- Cabin Type: Modular cabins are more cost-effective than custom-built units.

- Amenities: Premium features like internet or recreational spaces increase costs but enhance worker satisfaction.

- Compliance: Investments in safety and sanitation systems ensure long-term savings by avoiding fines.

Worker Welfare and Labour Camp Cabin

Worker welfare is a cornerstone of labour camp cabin design, directly impacting health, morale, and productivity in the DUBAI’s diverse workforce.

Amenities

- Living Spaces: Air-conditioned rooms with comfortable beds, personal lockers, and adequate lighting. Soundproofing reduces noise from nearby industrial activities.

- Dining Areas: Hygienic kitchens offering diverse cuisines (e.g., South Asian, Middle Eastern, African) to cater to multicultural workers.

- Recreational Facilities: Sports courts (e.g., cricket, football), TV rooms, libraries, or outdoor seating areas promote relaxation and social interaction.

- Medical Rooms: On-site clinics with basic supplies, first-aid kits, and trained staff. Isolation rooms for contagious illnesses ensure safety.

- Sanitation: Clean bathrooms and showers with hot/cold water, maintained daily to prevent health risks.

Mental Health

- Counseling Services: Access to professional counselors or peer support groups to address stress, homesickness, or isolation.

- Quiet Spaces: Dedicated areas for rest, meditation, or reading to support mental well-being.

- Community Events: Cultural festivals, movie nights, or sports tournaments foster camaraderie and reduce loneliness.

Productivity

- Proximity to Work Sites: Reduces commute times, allowing workers to rest and recharge, improving focus and efficiency.

- Comfortable Environments: Clean, well-ventilated cabins reduce fatigue, minimizing errors on the job.

- Skill Development: Study rooms or internet access enable workers to pursue online learning or certifications, enhancing career prospects.

Cultural Sensitivity

- Prayer Rooms: Equipped with prayer mats, qibla direction indicators, and space for daily prayers, essential for Muslim workers.

- Dietary Diversity: Kitchens offering halal, vegetarian, or regional dishes to accommodate dietary preferences.

- Multilingual Support: Signage and communication tools in languages like Arabic, Hindi, Urdu, or Tagalog to ensure accessibility.

Worker Feedback

- Surveys and Complaint Boxes: Allow workers to report issues like inadequate lighting, uncomfortable beds, or sanitation concerns.

- Regular Meetings: Engage workers in camp management decisions to address their needs.

- Actionable Improvements: Promptly address feedback, such as adding more recreational facilities or improving food quality.

Impact on Retention

Quality accommodations reduce turnover by:

- Creating a sense of belonging through community-focused designs.

- Improving health and comfort, reducing absenteeism.

- Demonstrating employer commitment to worker welfare, fostering loyalty.

Environmental Impact and Sustainability

Labour camp cabins are increasingly designed with sustainability in mind, aligning with DUBAI’s environmental goals and global green building standards.

Sustainable Materials

- Recycled Steel: Used for cabin frames, reducing resource consumption and landfill waste.

- Low-Impact Composites: Lightweight panels with minimal environmental footprint, ideal for modular designs.

- Biodegradable Insulation: Materials like cellulose or sheep’s wool provide thermal efficiency without harming the environment.

- Sustainable Concrete: Low-carbon mixes for foundations, reducing emissions during construction.

Energy Efficiency

- LED Lighting: Reduces electricity consumption by up to 80% compared to traditional bulbs.

- Solar Panels: Provide renewable energy for lighting, cooling, or water heating, particularly in remote camps.

- Smart Thermostats: Adjust air conditioning based on occupancy, minimizing energy waste.

- Energy-Efficient Appliances: Refrigerators, fans, and water heaters with high energy ratings.

Water Conservation

- Low-Flow Fixtures: Faucets and showerheads reduce water usage by 30–50%.

- Greywater Recycling: Reuses water from showers or laundry for irrigation or flushing.

- Rainwater Harvesting: Collects seasonal rainfall for non-potable uses, reducing reliance on municipal water.

Waste Management

- Recycling Programs: Separate bins for plastic, paper, and organic waste, with on-site sorting facilities.

- Composting: Food waste converted into fertilizer for camp landscaping.

- Efficient Disposal: Proper sewage systems prevent environmental contamination.

Green Certifications

- Estidama (Abu Dhabi): Camps can pursue Pearl Ratings for sustainable design and operations.

- LEED Certification: Aligns with global standards for energy efficiency and environmental impact.

- Local Compliance: Meets Dubai’s Green Building Regulations and Abu Dhabi’s sustainability mandates.

Environmental Challenges

- High Energy Demand: Air conditioning in extreme heat increases energy consumption, requiring renewable solutions.

- Waste in Remote Sites: Limited access to recycling facilities in desert areas complicates waste management.

- Construction Impact: Site preparation can disrupt local ecosystems, requiring careful planning.

Best Practices

- Use modular designs to minimize construction waste.

- Partner with local environmental agencies for waste disposal and recycling.

- Conduct environmental impact assessments before site selection.

- Educate workers on sustainable practices, such as water conservation and recycling.

Technology in Labour Camp Cabin

Technology is transforming labour camp cabins, enhancing functionality, safety, and worker satisfaction through innovative solutions.

Internet of Things (IoT)

- Environmental Monitoring: Sensors track temperature, humidity, and air quality, ensuring comfortable and safe conditions.

- Energy Management: Smart meters monitor electricity usage, optimizing consumption and reducing waste.

- Maintenance Alerts: IoT systems detect issues like leaks or HVAC failures, enabling proactive repairs.

Automation

- Facility Management Software: Automates maintenance schedules, tracks inspections, and generates compliance reports for MOHRE audits.

- Lighting Systems: Motion-activated LEDs reduce energy use in unoccupied areas.

- Climate Control: Automated thermostats adjust cooling based on occupancy or time of day.

Connectivity

- High-Speed Wi-Fi: Enables workers to connect with families, access online learning, or stream entertainment, reducing isolation.

- Digital Kiosks: Provide camp announcements, schedules, or feedback forms in multiple languages.

- Mobile Apps: Allow workers to report issues, access services, or participate in camp governance.

Security

- CCTV Systems: 24/7 surveillance with cloud-based storage ensures safety and deters theft.

- Biometric Access: Fingerprint or card-based entry systems restrict unauthorized access.

- Emergency Alerts: IoT-enabled alarms for fire, gas leaks, or medical emergencies, linked to local authorities.

Challenges

- Implementation Costs: Initial investment in smart systems can be significant, requiring long-term planning.

- Maintenance: Technical expertise is needed to service IoT and automation systems.

- Digital Divide: Some workers may lack familiarity with digital tools, requiring training.

Best Practices

- Partner with technology providers to integrate scalable, user-friendly systems.

- Train workers and staff on using digital tools effectively.

- Prioritize cybersecurity to protect IoT networks and worker data.

- Use modular technology that can be upgraded as innovations emerge.

Cultural Considerations in Labour Camp Design

DUBAI’s workforce is highly diverse, with workers from South Asia, Africa, the Philippines, and beyond. Labour camp cabins must address cultural needs to ensure inclusivity and worker satisfaction.

Multicultural Workforce

- Demographics: Workers hail from countries like India, Pakistan, Bangladesh, Nigeria, and the Philippines, each with unique traditions, languages, and dietary preferences.

- Cultural Sensitivity: Camps must avoid uniform designs, instead catering to diverse needs to foster a sense of belonging.

Cultural Amenities

- Prayer Rooms: Essential for Muslim workers (over 50% of the workforce), with qibla direction indicators, prayer mats, and space for daily prayers. Non-Muslim workers may need spaces for other religious practices.

- Diverse Dining: Kitchens offering halal, vegetarian, or regional dishes (e.g., biryani, injera, adobo) to accommodate dietary preferences. Separate dining areas for dietary restrictions enhance inclusivity.

- Language Support: Multilingual signage in Arabic, Hindi, Urdu, Tagalog, and English for accessibility. Digital apps or kiosks can provide translations for announcements or instructions.

- Cultural Spaces: Areas for traditional games (e.g., carrom, chess) or cultural performances to celebrate worker heritage.

Community Building

- Cultural Events: Festivals like Diwali, Eid, or Christmas celebrations foster inclusivity and reduce homesickness.

- Sports and Recreation: Cricket, football, or volleyball tournaments engage workers from diverse backgrounds.

- Community Leaders: Appoint worker representatives to address cultural concerns and mediate disputes.

- Social Support: Peer groups or counseling services help workers navigate cultural adjustments and isolation.

Challenges

- Dietary Diversity: Providing varied cuisines requires skilled kitchen staff and diverse suppliers.

- Space Constraints: Adding cultural amenities in compact camps can be challenging.

- Language Barriers: Ensuring all workers understand safety and camp rules requires multilingual communication.

Best Practices

- Conduct worker surveys to identify cultural needs during camp planning.

- Partner with cultural organizations to design inclusive amenities.

- Train facility managers on cultural sensitivity to address diverse worker needs.

- Create flexible spaces that can adapt to different cultural activities.

Health and Safety Standards in Labour Camps

Health and safety are paramount in labour camp cabins, with regulations ensuring worker protection in the DUBAI’s challenging environment.

Fire Safety

- Materials: Fire-resistant panels (e.g., steel, gypsum) and coatings to prevent fire spread.

- Equipment: Smoke detectors, fire extinguishers (one per 50 workers), and sprinkler systems in larger camps.

- Training: Quarterly fire drills and worker education on evacuation procedures.

- Exits: Clearly marked emergency exits, with at least one per 50 workers, unobstructed and well-lit.

Sanitation

- Bathrooms: One toilet per 25 workers, with daily cleaning and proper sewage connections.

- Showers: Hot and cold water, with low-flow fixtures to conserve water.

- Laundry: Washing machines or laundry services, with one unit per 50 workers.

- Waste Management: Daily waste collection, with separate bins for recycling and organic waste.

Medical Facilities

- On-Site Clinics: Equipped with first-aid kits, basic medications, and trained nurses or paramedics.

- Isolation Rooms: For contagious illnesses, with ventilation and sanitation protocols.

- Hospital Partnerships: Agreements with local hospitals for emergency care or specialist referrals.

- Health Screenings: Regular checks for communicable diseases, particularly in high-density camps.

2025 Updates

- Ventilation Standards: HEPA filters or equivalent systems to improve air quality and reduce airborne disease risks.

- Social Distancing: Maximum 6 workers per shared room, with 1-meter spacing between beds.

- Mental Health: Mandatory counseling services or wellness programs to address worker stress.

- Emergency Preparedness: Enhanced protocols for pandemics, including quarantine areas and rapid testing.

Challenges

- Climate: Extreme heat and humidity require robust cooling and ventilation systems.

- Compliance Costs: Upgrading older camps to meet 2025 standards can be resource-intensive.

- Worker Education: Ensuring all workers understand safety protocols in multiple languages.

Best Practices

- Conduct regular safety audits to identify and address risks.

- Train workers on fire safety, first aid, and hygiene practices.

- Partner with health authorities to ensure medical compliance.

- Use technology (e.g., IoT sensors) to monitor safety conditions in real-time.

Maintenance and Upkeep of Labour Camp Cabin

Ongoing maintenance ensures labour camp cabins remain safe, functional, and compliant with DUBAI regulations.

Regular Inspections

- Structural Checks: Monthly assessments of walls, roofs, and foundations for wear, cracks, or weather damage.

- Utility Audits: Verify electricity, water, and sewage systems for reliability and efficiency.

- Compliance Reviews: Quarterly inspections by MOHRE or local authorities to ensure adherence to space, safety, and sanitation standards.

Utility Management

- Electricity: Monitor usage to prevent outages, with backup generators for critical systems like air conditioning.

- Water: Ensure potable water supply and regular testing for contamination.

- Internet: Maintain high-speed connectivity for worker communication and camp management apps.

- HVAC Systems: Clean and service air conditioning units monthly to maintain cooling efficiency in extreme heat.

Repairs

- Structural Repairs: Address damaged walls, roofs, or floors caused by sandstorms or wear and tear.

- Plumbing: Fix leaks, clogs, or sewage issues promptly to maintain sanitation.

- Electrical: Repair faulty wiring or lighting to ensure safety and functionality.

- Weatherproofing: Apply coatings or sealants to protect against humidity, heat, or sand abrasion.

Worker Feedback

- Surveys: Collect feedback via anonymous surveys or digital apps to identify issues like uncomfortable beds or inadequate lighting.

- Complaint Boxes: Provide physical or digital channels for workers to report maintenance needs.

- Action Plans: Implement improvements based on feedback, such as adding fans or upgrading mattresses.

Challenges

- Harsh Climate: Heat, humidity, and sandstorms accelerate wear, requiring frequent repairs.

- Resource Constraints: Large camps need dedicated maintenance teams, increasing operational demands.

- Worker Expectations: Diverse workforces may have varying standards for comfort and cleanliness.

Best Practices

- Create a maintenance schedule with daily, weekly, and monthly tasks.

- Train facility staff on rapid repair techniques and compliance standards.

- Use IoT sensors to detect issues like leaks or HVAC failures in real-time.

- Engage workers in maintenance planning to ensure their needs are met.

Financing and Investment in Labour Camp Cabin

Financing labour camp cabins involves balancing initial investments with long-term benefits, with options for renting or purchasing.

Rental Financing

- Short-Term Leases: Ideal for projects lasting 6–24 months, with suppliers providing pre-furnished cabins and maintenance services.

- Utility Inclusion: Leases often cover electricity, water, and internet, simplifying budgeting.

- Flexible Terms: Options to extend or terminate leases based on project timelines.

Purchase Financing

- Long-Term Investment: Suitable for projects spanning 3+ years, allowing ownership and customization.

- Customization Costs: Expenses for industry-specific features, such as explosion-proof materials or cultural amenities.

- Site Preparation: Includes foundations, utility connections, and access roads.

Government Incentives

- Subsidies: Available for camps meeting sustainability or compliance standards, such as Estidama or 2025 regulations.

- Tax Benefits: Employers investing in worker welfare may qualify for tax deductions.

- Grants: Support for eco-friendly designs, such as solar-powered cabins.

Challenges

- Upfront Costs: Purchasing cabins requires significant initial investment, particularly for custom designs.

- Maintenance Burden: Owned cabins shift maintenance responsibilities to employers.

- Regulatory Changes: New standards may require costly upgrades to existing cabins.

Best Practices

- Conduct cost-benefit analyses to compare renting vs. buying based on project duration.

- Partner with suppliers offering flexible financing plans.

- Leverage government incentives to offset sustainability investments.

- Plan for scalability to accommodate future workforce growth.

Worker Perspectives on Labour Camp Cabin

Understanding worker experiences is critical to designing effective labour camp cabins, ensuring they meet practical and cultural needs.

Living Conditions

- Comfort: Workers value air-conditioned rooms, comfortable beds, and personal storage for belongings. Soundproofing reduces noise from industrial sites or roommates.

- Privacy: Semi-private or private rooms are preferred, though shared rooms (5–8 workers) are common in budget-conscious camps.

- Cleanliness: Daily cleaning of bathrooms, kitchens, and communal areas is essential for health and satisfaction.

Challenges

- Overcrowding: Older camps may exceed capacity, leading to discomfort and health risks.

- Isolation: Remote camps lack access to cultural or recreational facilities, causing loneliness.

- Maintenance Delays: Slow responses to issues like broken air conditioning or plumbing reduce satisfaction.

- Cultural Gaps: Lack of dietary diversity or religious facilities can alienate workers.

Improvements Suggested by Workers

- More Recreational Spaces: Gyms, sports courts, or libraries to support relaxation.

- Better Food Options: Diverse cuisines and vegetarian/halal choices to meet dietary needs.

- Faster Maintenance: Quicker repairs for utilities, lighting, or sanitation issues.

- Internet Access: High-speed Wi-Fi for communication and online learning.

- Cultural Amenities: Prayer rooms, cultural events, and multilingual support to enhance inclusivity.

Testimonials

- Positive Feedback: Workers in well-designed camps report higher morale, citing clean facilities, recreational areas, and proximity to work sites.

- Critical Feedback: Complaints focus on overcrowding, slow maintenance, or lack of cultural amenities in older camps.

- Success Stories: Workers in camps with community events (e.g., cricket tournaments) note stronger camaraderie and reduced homesickness.

Best Practices

- Conduct regular worker surveys to identify pain points and preferences.

- Establish feedback channels (e.g., apps, complaint boxes) for real-time reporting.

- Act on suggestions promptly to build trust and improve conditions.

- Involve workers in camp design to ensure cultural and practical needs are met.

Labour Camp Cabin in Remote vs. Urban Settings

Labour camp cabins vary significantly between remote and urban environments, each presenting unique challenges and benefits.

Remote Settings

- Design: Durable, containerized cabins with heat-resistant coatings and self-contained utilities (e.g., solar power, water tanks).

- Applications: Oil and gas projects, desert infrastructure, or coastal developments.

- Benefits:

- Proximity to remote sites reduces travel time and costs.

- Self-contained designs ensure functionality without external infrastructure.

- Portable cabins allow relocation as projects move.

- Challenges:

- Limited access to utilities, requiring on-site generators or water storage.

- Isolation from cultural or recreational amenities, impacting worker morale.

- Higher transportation costs for materials and workers.

Urban Settings

- Design: Permanent or modular cabins integrated with city infrastructure, with access to public utilities and transport.

- Applications: Construction projects, logistics hubs, or hospitality sectors in cities like Dubai or Abu Dhabi.

- Benefits:

- Access to public transport, supermarkets, and medical facilities enhances convenience.

- Urban camps integrate with local communities, reducing isolation.

- Existing infrastructure simplifies utility connections.

- Challenges:

- Higher land costs in urban areas increase setup expenses.

- Stricter regulations (e.g., Dubai Municipality) require rigorous compliance.

- Traffic congestion may complicate worker transport.

Design Differences

- Remote Cabins: Prioritize portability, weather resistance, and self-sufficiency. Features include insulated walls, solar panels, and compact layouts.

- Urban Cabins: Focus on integration with city systems, with larger communal areas and accessibility features like ramps.

- Material Choices: Remote cabins use corrosion-resistant coatings for coastal or desert environments, while urban cabins use standard steel or composites.

Best Practices

- Assess site conditions (e.g., climate, infrastructure) before selecting cabin types.

- Design remote camps with recreational facilities to combat isolation.

- Ensure urban camps comply with local zoning and safety regulations.

- Use modular designs for flexibility in both settings.

Role of Labour Camp Cabin in DUBAI’s Construction Boom

Labour camp cabins are integral to DUBAI’s construction sector, supporting its rapid growth and ambitious projects.

Construction Sector Overview

- DUBAI’s construction industry is a cornerstone of its economy, driven by projects like skyscrapers, metro systems, airports, and cultural districts.

- Migrant workers, housed in labour camps, form the majority of the construction workforce, enabling large-scale developments.

Role of Labour Camps

- On-Site Housing: Cabins near project sites reduce commute times, allowing workers to focus on productivity.

- Scalability: Modular designs accommodate fluctuating workforce sizes, supporting phased projects.

- Compliance: Camps ensure adherence to MOHRE regulations, avoiding project delays due to penalties.

- Worker Welfare: Quality accommodations improve morale and retention, enhancing project quality.

Major Projects Supported

- Dubai: Expo 2020 legacy developments, Dubai Creek Tower, and residential expansions rely on labour camps for thousands of workers.

- Abu Dhabi: Cultural projects like the Louvre Abu Dhabi and infrastructure developments in Yas Island use camps to house workers.

- Sharjah and Ras Al Khaimah: Smaller-scale projects, such as industrial zones or tourism facilities, benefit from cost-effective camps.

Economic Contributions

- Workforce Stability: Quality camps reduce turnover, ensuring consistent labor for long-term projects.

- Project Efficiency: On-site housing minimizes delays, enabling faster completion of high-profile developments.

- Local Economy: Camps create jobs in maintenance, catering, and security, supporting local communities.

Challenges

- Capacity Planning: Rapid project growth requires scalable camp designs to avoid overcrowding.

- Regulatory Pressure: Stricter 2025 standards demand ongoing upgrades to older camps.

- Worker Expectations: Diverse workforces require tailored amenities to maintain satisfaction.

Best Practices

- Align camp development with project timelines and workforce needs.

- Invest in worker-centric designs to boost productivity and retention.

- Partner with local authorities to ensure compliance and streamline permitting.

- Use sustainable designs to align with DUBAI’s green construction goals.

Legal and Ethical Considerations

Labour camp cabins operate within a complex legal and ethical landscape, requiring employers to balance compliance with fair treatment.

Legal Obligations

- MOHRE Regulations: Mandate accommodation for companies with 50+ low-wage workers, with standards for space, safety, and amenities.

- Emirate-Specific Rules: Dubai, Abu Dhabi, and Sharjah have unique requirements for zoning, sanitation, and fire safety.

- Documentation: Employers must maintain records of worker assignments, maintenance schedules, and compliance audits.

- Inspections: Regular checks by MOHRE or local authorities ensure adherence to standards.

Ethical Concerns

- Kafala System: Historically, this system limited worker mobility and rights, tying workers to employers and restricting their ability to address housing issues. Recent reforms have improved mobility, but challenges remain.

- Worker Dignity: Ethical employers prioritize clean, safe, and culturally sensitive accommodations to respect workers’ rights.

- Transparency: Addressing worker complaints promptly and transparently builds trust and prevents exploitation.

- Fair Treatment: Providing equal access to amenities and opportunities for all workers, regardless of nationality or role.

Improvements

- 2025 Regulations: Enhanced standards for ventilation, social distancing, and mental health support reflect a commitment to worker welfare.

- Worker Advocacy: Channels like MOHRE’s complaint hotline empower workers to report issues anonymously.

- Global Standards: Alignment with International Labour Organization (ILO) guidelines promotes ethical practices.

- Corporate Responsibility: Employers are encouraged to select suppliers with ethical track records and transparent operations.

Challenges

- Compliance Costs: Upgrading camps to meet 2025 standards requires significant investment.

- Cultural Diversity: Addressing the needs of a multicultural workforce can be complex and resource-intensive.

- Enforcement Gaps: While regulations are strict, inconsistent enforcement in remote areas can allow substandard camps to persist.

Best Practices

- Conduct regular compliance audits to ensure adherence to legal standards.

- Establish worker councils to represent diverse voices and address concerns.

- Partner with advocacy groups to promote ethical labor practices.

- Educate employers and workers on their rights and responsibilities under DUBAI law.

Conclusion

Labour camp cabins are a vital component of DUBAI’s industrial and economic landscape, providing safe, compliant, and efficient housing for its diverse workforce. From their modular designs and stringent regulatory requirements to their cultural, environmental, and economic significance, these cabins reflect DUBAI’s commitment to balancing rapid development with worker welfare. By addressing historical challenges, embracing technological and sustainable innovations, and prioritizing worker needs, labour camp cabins are poised to play an even greater role in DUBAI’s future.

Frequently Asked Questions

- What is a Labour Camp Cabin?

A modular, prefabricated unit designed to house workers in compliance with UAE labour accommodation standards. - Who Needs to Provide Labour Camp Accommodation?

Employers with 50 or more workers earning less than AED 1,500/month must provide accommodation. - What Are the Space Requirements?

Each worker must have at least 3 square meters of personal space in sleeping quarters. - What Facilities Are Mandated?

Cabins must include air conditioning, proper lighting, ventilation, and access to sanitation facilities. - Are There Limits on Room Occupancy?

Yes, a maximum of 8 workers per room is permitted to prevent overcrowding. - What Safety Measures Are Required?

Compliance with fire safety regulations, including fire extinguishers and emergency exits, is mandatory. - Is Transportation Provided?

Employers must provide transportation if the camp is located far from the workplace. - How Are Labour Camps Inspected?

Dubai Municipality conducts regular inspections to ensure compliance with health and safety standards. - What Are the Consequences of Non-Compliance?

Employers may face fines, camp closure, or suspension of operations. - How Can Employers Ensure Compliance?

Regular audits, staff training, and adherence to government regulations help maintain compliance.